When you hold your favorite product in your hands, you probably rarely think about the journey its packaging has taken to become so attractive and functional.

Most people don't think about the packaging, they focus on the product and its features.

However, packaging plays an important role both in the perception of the quality of a product and in the purchase decision, and should not be overlooked.

Today, you will take a step into our world for a moment and discover the whole process behind the unique packaging of a product, from idea to execution.

Enquiry: First, you let us know of your requirements and preferences regarding the packaging you want to order. Together, we will explore your needs and goals and make sure that the packaging is perfectly tailored to your product. We need the following information from the customer: the type of the product, its dimensions, its weight, its position on the market - is it a higher or lower priced product. Perhaps you can even send us the product so we can design the packaging around it.

Cost estimation: Based on your enquiry, our team of technologists will prepare a detailed cost estimate covering materials, implementation and possible additional services.

Offer: Based on the calculation, we will prepare a customized offer including price, estimated production time and other relevant information. We will send you the offer in a suitable format for you to view in detail.

When you send us a formal order, we will ask you to send us the desired graphic for the packaging and our sales team will start preparing your packaging.

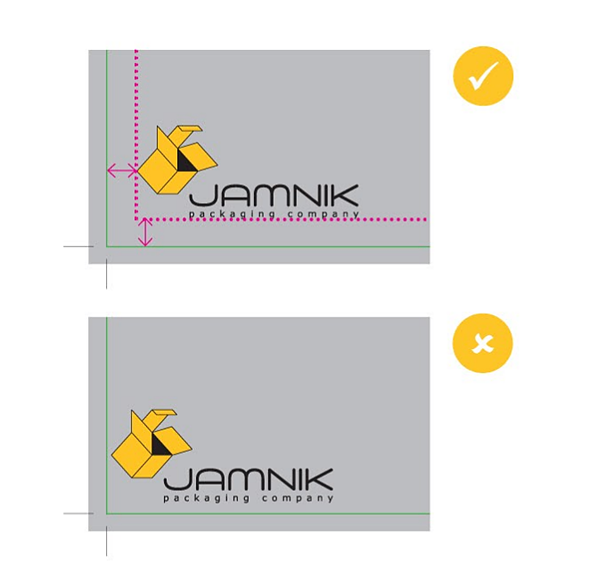

Sample confirmation and print file: We will send you an (unprinted) sample of the packaging for confirmation before the production starts. The sample is produced in the office on a cutting machine and used for you to check the dimensions, material, load capacity, construction and opening of the packaging before production. In addition, you will receive a link to a pdf file so that you can check the final graphic design of the packaging.

Did you know that in 2009 we installed our own pre-press department and in 2017 we acquired our own CTP platesetter for production of printing plates, which allows us to quickly yet thoroughly check incoming print files, make any necessary corrections, prepare forms for printing and create all kinds of effects and tools for further production.

We can also provide the customer with a 3D presentation of the design before printing.

Materials sourcing and planning: After you approve the sample and the print file, our team will carefully select the materials. The order will be placed in the production plan depending on the material delivery date. At this stage, our sales team will send you an order confirmation and the delivery date.

We aim to confirm the delivery date of the packaging within 48 hours of the file confirmation, so you are informed on time.

Production: Packaging is produced according to schedule in our production facility, which ensures quality and precision.

Final processing and dispatch: Once production is complete, the packaging ready for dispatch is transferred to the outgoing warehouse. A delivery note is prepared for each consignment to ensure traceability.

Invoice: Once the packaging has been delivered, you will be invoiced for the cost of materials, production and other agreed services.

Although most people may not be aware of the packaging production process, it is important to be aware of the role it plays. Packaging is vital for maintaining product quality, simplifying our lives and protecting the environment. It is also an important aspect of marketing and branding.

Remember that every package contains a story that has been written with love, passion and attention to detail.

|

|